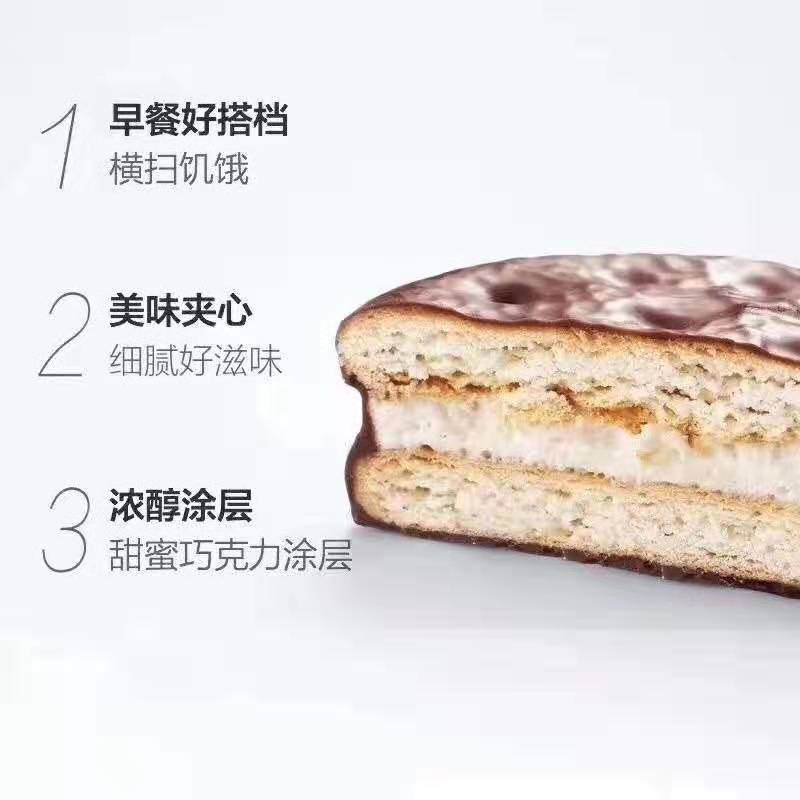

餅片展示

產品詳情

巧克力派生產線

巧克力派生產線系本公司獨立自主研發的新型棉花糖注心派生產設備。該設備自動化程度高,整個流程分為三大部分:

1棉花糖充氣攪拌整個流程經過熬糖,冷卻,充氣攪拌,將成品糖通過壓力加入澆注罐

2棉花糖注心派生產這部分通過落餅,翻面,排餅,注水,棉花糖澆注,機械手蓋餅完成主餅片的制作

3巧克力涂層餅片經過巧克力涂層,冷卻隧道冷卻,直接送入包裝機

整個設備采用PLC,觸摸屏進行控制與操作,操作簡單,整個設備運行穩定,以精致的設計,嚴謹的生產工藝,精密的制造,確保了生產過程的安全,可靠,衛生。

本設備生產的巧克力派,口感較好,形狀規則,由于生產工藝的復雜性,屬于同類休閑產品中的高端產品,具有廣闊的市場。

The Chocolate Pie Production Line is a newly developed cotton candy filling pie production equipment which is highly automatic.The production process is decomposed into three main steps.

1.Cotton Candy Inflating and Mixing

After sugar boiling,cooling,inflating and mixing,the machine would press the finished sugars into the pouring tank.

2.Cotton Candy Filling Pie Production

After cake dropping,cake turning,cake arranging,water injecting,cotton candy pouring,the manipulator will cover the cake to finish the production.

3.Chocolate Coating

The cakes will be transferred through the chocolate coating line and cooling tunnel,and then they will be sent to the packer.

This equipment adopts PLC(touch screen)to control and operate.The simple operation,stable operation,exquisite design,accurate production technique and precise manufacturing guarantee the safety,reliability and hygiene of the production process.

The product of this production line has a good taste and a regular shape.It can be highly ranked among similar products because of its complex production technique,and it has a good market prospect.

1.尺寸:7000*1450*2800

2.材質:機架201不銹鋼,與食品接觸位置304不銹鋼

3.產品規格:Φ55mm-62mm 25-30g/個

4.產量:388-432kg/h;18-20排/分鐘;

5.棉花糖儲存罐2個;加熱水罐1個;

6.電量:380V 7kw

7.氣量:0.8MPA壓縮空氣

8.水循環加熱功率:8kw

9.重量:2000kg

關鍵詞: 巧克力派生產線